Case Study: Transforming Hole Finishing with Samtec’s Noga UBurr Solution

🔧 The Challenge

A leading automotive components manufacturer struggled with deburring drilled through-holes:

- Manual rework slowed production

- Inconsistent quality and burr-related defects

- Extra handling from part flipping increased cycle times

- Higher production costs due to labour-intensive processes

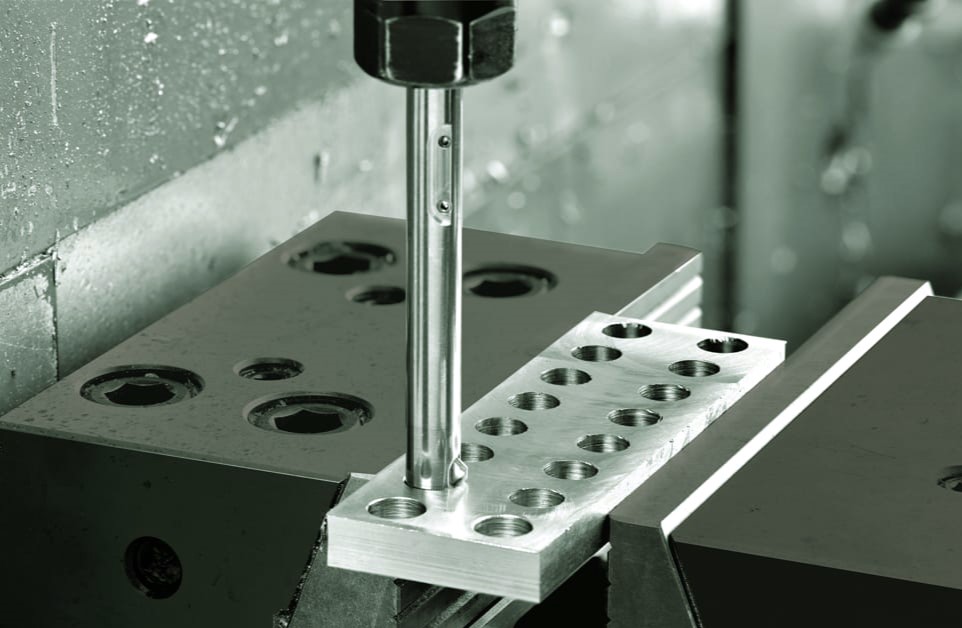

💡 The Solution: UBURR

Samtec introduced the Noga MT-UBURR tool, engineered to deburr both front and back edges of drilled holes in a single pass.

UBURR Benefits:

- Eliminates part flipping

- Burr-free, clean edges every time

- Faster, consistent results in high-volume production

- Easy CNC integration — no extra workstation needed

📈 The Results

After 6 months of using UBURR, the customer reported:

- 40% faster cycle times

- Zero burr-related defects

- Reduced operator intervention

- Superior finish quality meeting global standards

💬 Customer Testimonial

"UBURR completely changed how we approach deburring. No more part flipping, no more rework — just consistent, burr-free results in one pass. It has improved both speed and quality in our machining lines."

Video

🌍 Applications

UBURR is ideal for:

- 🚗 Automotive → Engine blocks, gears, safety parts

- ✈️ Aerospace → Critical fastener holes & precision components

- ⚙️ Industrial → Pumps, valves, heavy machinery

✅ Conclusion

By adopting UBURR, manufacturers can:

- Eliminate manual bottlenecks

- Shorten lead times

- Improve part quality

- Increase profitability

Get in Touch

Copyright © 2025 Samtectools

Best viewed in IE 10+, Firefox 20+, Chrome , Safari5+, Opera12+